- Frictional Engagement between the lateral wedge surfaces require a large cross-section and high stiffness of V-belts

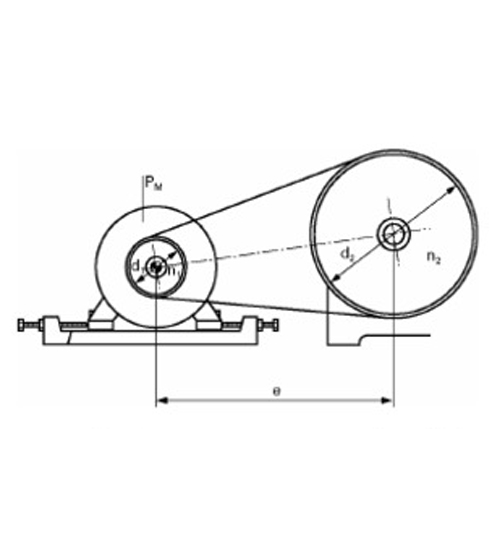

- High Energy loss due to cyclic bend

- V-belts are wedging in the grooves and pulling out from grooves

- Energy loss and high wear

- Frcitional Engagement between lateral wedge surfaces of the belt profile

- Large bending cross-section, large mass

- Different effective diameters and thus varying speeds of individual belts